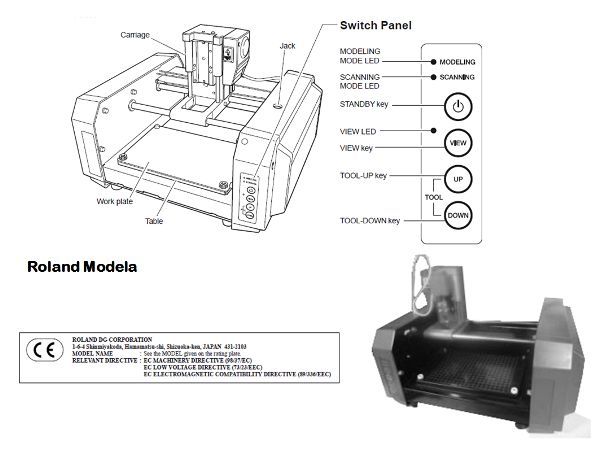

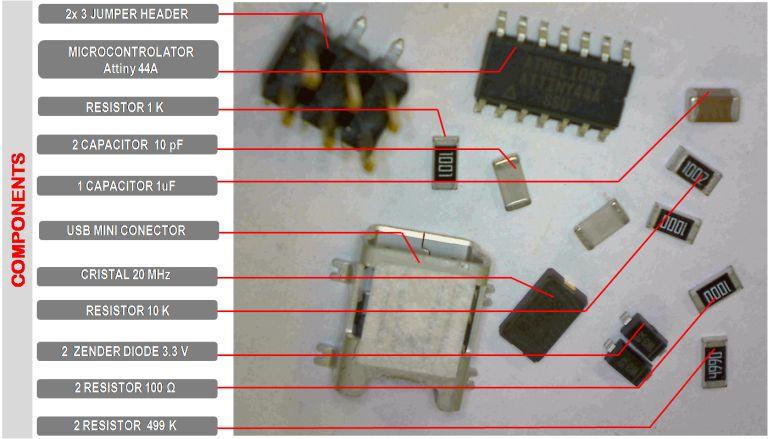

This week we are to learn how to make the FabISP in-circuit programmer. To which will make the following steps: Machining (use of the machine Roland Modela); Soldering (SMD components) and finally Programing the Fab ISP board.

1. MACHINING - Some material and tools:

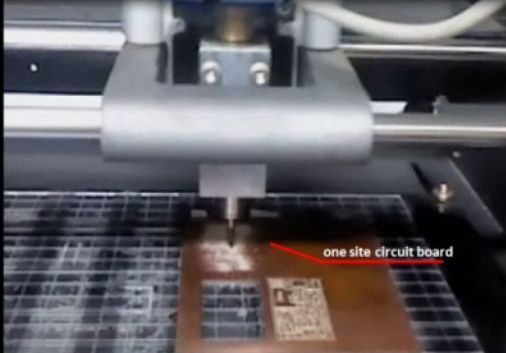

- One side circuit board

- Mills: 1/32" mm (milling); 1/64" mm (cutting)

- Double side tape: Fix the board to working area

- Torkey and limaton: To adjust the mills

- Multimeter: Measure the value of components (verify the connection of the board)

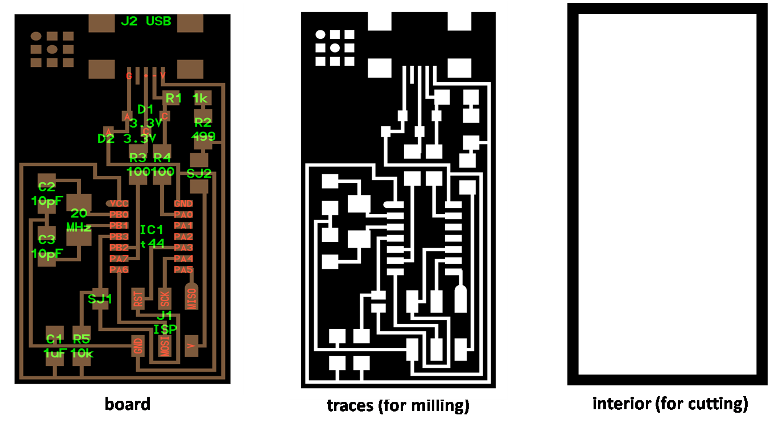

"hello.ISP.44.cad board components traces interior"

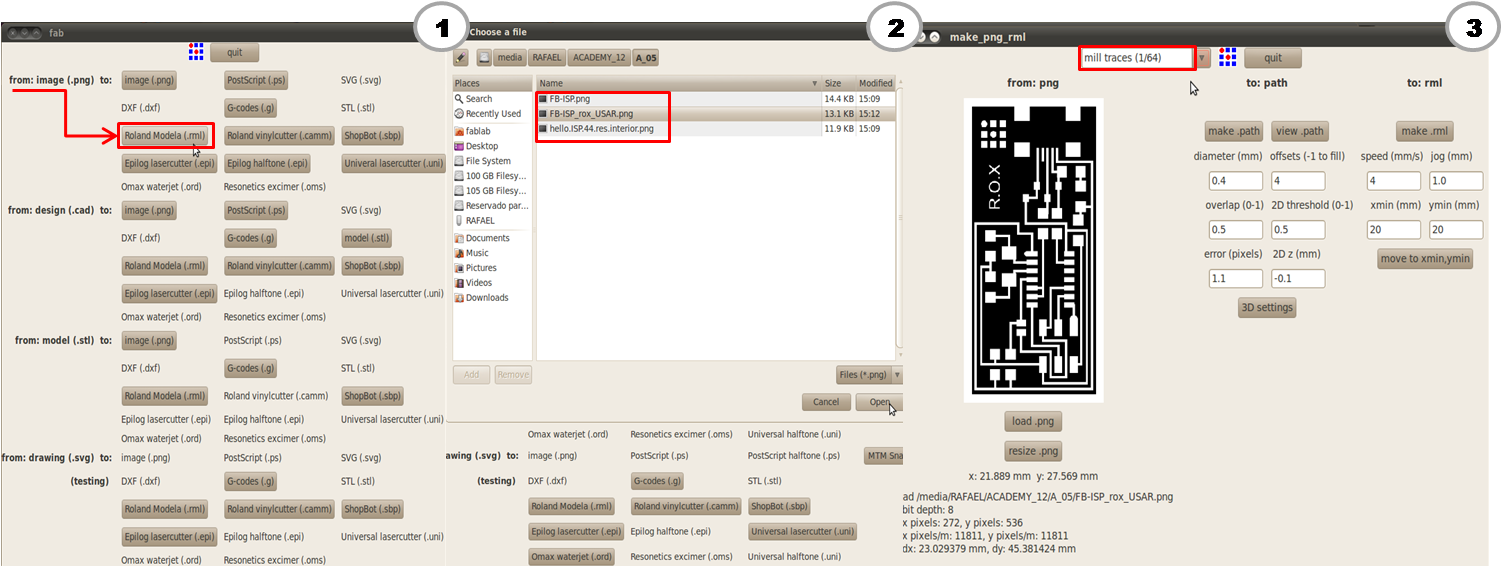

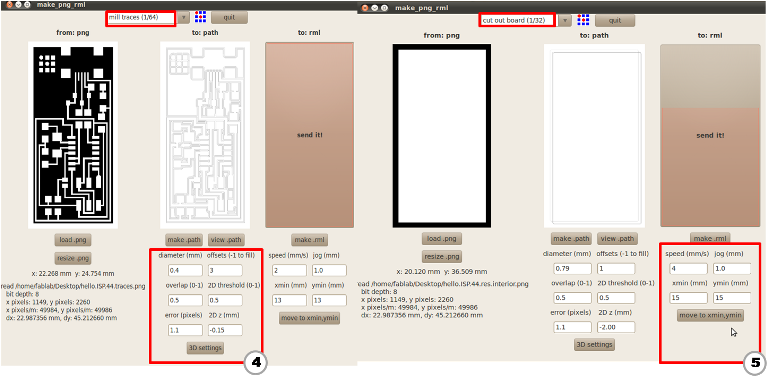

Open the traces files, then send to machine the board to the Roland Model, we must import the design in .png format. Begin milling circuit, then finishing with the internal edge cut (for ubuntu should be installed Fabmodules)

1.Open window: fab modules:2.Enter [from image (png)] – Roland Modela3.Load the image4.Data set for the work of the tool and set speed and origin point

Machining process:

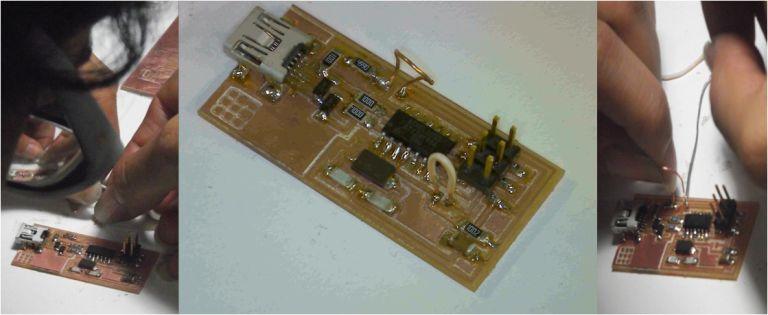

Before starting the machining, paste the circuit board in the working area with double side tape. Then use the mill tool of 1/64" for milling and 1/32" for cutting. The adjustment of the tool is manual, for which we use the allen wrench. when machining process is complete, push the "view" botton of the Modela and then to proceed to vacuuming to remove residue.

3. PROGRAMING: Testing and programing our Fab ISP

Connect the programmer AVR in our board through a serial port at the entrance J6 Jumper .Connect our board to a laptop through a USB cable.Check operation: if the light is red means not the energy is coming, if you turn the light is green means everything is ok!Once verified proceed to program our circuit board. We'll do it from Ubuntu and run the follow commands: